As the efficiency gap between N-type and P-type cells widens, the competitiveness of N-type products such as HJT, TOPCon, and XBC becomes increasingly highlighted, ushering in the photovoltaic industry's accelerated shift towards the "N-type" era. Simultaneously, TOPCon cell, with its superior performance features of high efficiency, high bifaciality, and low degradation, the relative maturity of equipment and process advantages, and economic advantages such as compatibility with PERC production lines and low equipment upgrade costs, have seized the initiative in the early stage of N-type technology penetration, becoming one of the mainstream cell technologies with high cost-effectiveness widely recognized by the market.

Definition and Principle of TOPCon

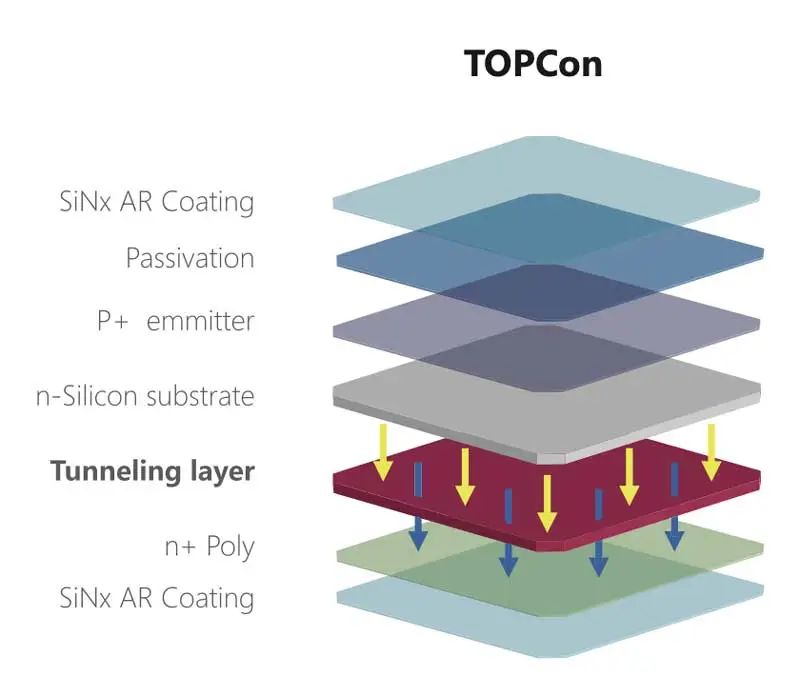

TOPCon (Tunnel Oxide Passivating Contact), is an advanced N-type silicon cell technology originated in 2013. TOPCon cell is a solar cell with tunnel oxide passivated contact based on N-type silicon substrate. Compared with PERC cells, TOPCon utilizes tunnel oxide as the charge transfer layer on the back of the cell, and then deposits a doped polysilicon thin layer of about 20 nm, forming a back passivation contact structure that can effectively reduce surface composition and metal contact composition, enhance open-circuit voltage, and boost energy conversion efficiency.

▲Source: Solar Analytica

Advantages of TOPCon in the Early Stage of Technological Iteration

From a performance perspective, TOPCon has the following advantages: 1) High conversion efficiency. Benefits form the unique passivating contact design of TOPCon cell, its theoretical conversion efficiency limit reaches as high as 28.7%, while the mass production efficiency of leading TOPCon manufacturers has exceeded 25.5%, a significant improvement compared to mainstream PERC cells (current mass production conversion efficiency is 23.5%, with a theoretical limit of 24.5%). 2) High bifaciality. TOPCon bifacial cells produce 2-3% more per-watt power generation than bifacial PERC cells, leading to higher power generation gains in the same ground station application scenario. 3) Low temperature coefficient. The temperature coefficient of N-type TOPCon modules is as low as -0.30%/℃, which is superior to the -0.35%/℃ of P-type modules, exhibiting excellent stability in high-temperature environments. 4) Low degradation. The boron content in phosphorus-doped N-type crystalline silicon is extremely low, basically no boron-oxygen composition, and thus providing a degradation rate advantage. AKCOME's TOPCon modules have a first-year degradation of 1% and a linear annual degradation of 0.4%, significantly better than the 2% first-year and linear 0.45% degradation of PERC modules, leading to higher single-watt module power generation gains throughout the lifecycle. 5) Superior performance in low light conditions. TOPCon cells can effectively respond to both short and long wavelengths, ensuring excellent power generation capability under low light conditions such as early morning, late afternoon, and cloudy days.

From an economic perspective, TOPCon has the following advantages: 1) Highly compatible with the PERC cell manufacturing process, reducing the difficulty of technology upgrades. TOPCon can be extended based on PERC process technology, requiring only the addition of steps such as the preparation of the boron emitter, growth of tunnel oxide layer, deposition of polysilicon and its doping, and post-diffusion cleaning. This reduces the difficulty of technological upgrading and accelerates the promotion of TOPCon technology. 2) Smooth production line conversion, low equipment investment cost. The equipment investment required for a new TOPCon production line is between 200-250 million yuan, while that for a new HJT production line is between 350-400 million yuan. However, TOPCon is highly compatible with existing PERC production lines, requiring only the addition of LPCVD/PECVD/PVD equipment for boron diffusion and polysilicon/amorphous silicon deposition. The equipment investment is 50-70 million yuan, avoiding large-scale investment in new equipment and extensive renovations to production lines, thus making it economically advantageous. 3) TOPCon products have a large premium potential. TOPCon modules, compared to PERC modules, have higher per-watt power generation, higher power generation gains, and lower system costs, thus providing a larger premium space.

Accelerating Penetration of TOPCon

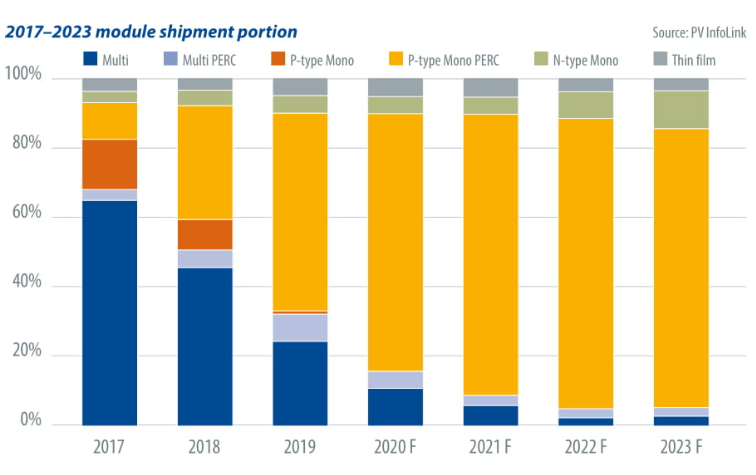

TOPCon technology has gradually been applied and is showing a significant growth trend. According to statistics from the China Photovoltaic Industry Association (CPIA), "The market share of TOPCon cells has risen from 3% in 2021 to 8.9% in 2022, and is expected to reach 21.1% in 2023." According to PV InfoLink, by the end of 2023, the nominal capacity of TOPCon is expected to exceed 600GW, and module shipments are expected to reach about 120GW. The market share of TOPCon module products in 2023 is expected to reach 25-30%, and it is likely to grow to about 60% in 2024.

▲Source: PV InfoLink

In the future, with the thinning of silicon wafers, the reduction of silver paste consumption, and the advancement of the process of equipment localization, TOPCon costs will be further reduced. Combined with efficiency-improving methods such as SE laser doping, bifacial POLY, and laminated cells, the efficiency and power generation of TOPCon will continue to improve, injecting vitality into the large-scale commercial production of N-type technology.

AKCOME Leads the Future of N-type

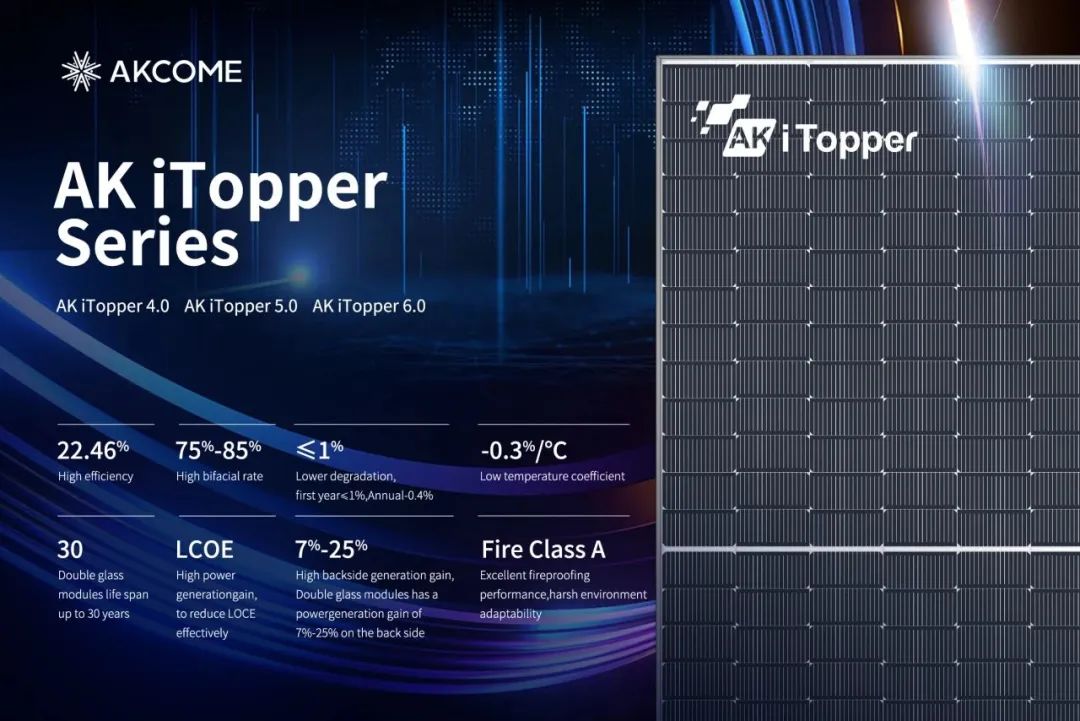

In recent years, the global photovoltaic market has witnessed robust demand, propelling the industry to experience an expedited transition towards N-type technologies. With long-standing technological research advantages and manufacturing experience, AKCOME has initiated a dual-wheel driven business development model labelled "HJT+TOPCon". Concentrating on the industrialisation of high-efficiency heterojunction cells and modules, AKCOME has concurrently laid out TOPCon production strategies, thereby pioneering the mainstream N-type photovoltaic trajectory. In terms of TOPCon modules, AKCOME currently provides three high-efficiency series, namely AK iTopper 4.0/5.0/6.0.

▲ AK iTopper Series TOPCon Module

AKCOME's TOPCon double-glass modules feature a bifaciality of 75-85%, with the rear side contributing a power generation gain of 7%-25%, effectively increasing energy output compared to P-type modules. The first-year degradation is merely 1%, and the linear annual degradation rate is 0.4%, ensuring a power output of no less than 89.4% over a span of 25 years. The unique surface passivation layer provides TOPCon with an efficiency advantage. AKCOME's TOPCon modules can achieve a maximum conversion efficiency of 22.46%, and have great potential for efficiency enhancement, promising higher energy output over the entire lifecycle.

Embracing N-type technology is not only responding to industry trends and market demands, but also reflects the aspiration of businesses for constant innovation and accelerated iterative upgrades. AKCOME will continue to amplify our commitment to research and development, facilitating high-efficiency and cost-effective strategies, and contribute to the high-quality development of the N-type industrialization.

Horário de atendimento: 8: 00-17: 00 em dias úteis

HQ: 0571-89089399

Sales: +86-512 8255 7328

Mail: modulesales@akcome.com

Sede: Sala 901, Edifício 1, No. 1818-2, Wenyi West Road, Rua Yuhang, Distrito de Yuhang, Cidade de Hangzhou, Província de Zhejiang